Manufacturing Consulting: CaseWhen Consulting

Unlock the Power of Manufacturing Excellence

What is Manufacturing Consulting?

10 KPIs of Manufacturing Consulting

How is Consulting Used in Business Transformation?

Enhanced Operational Efficiency

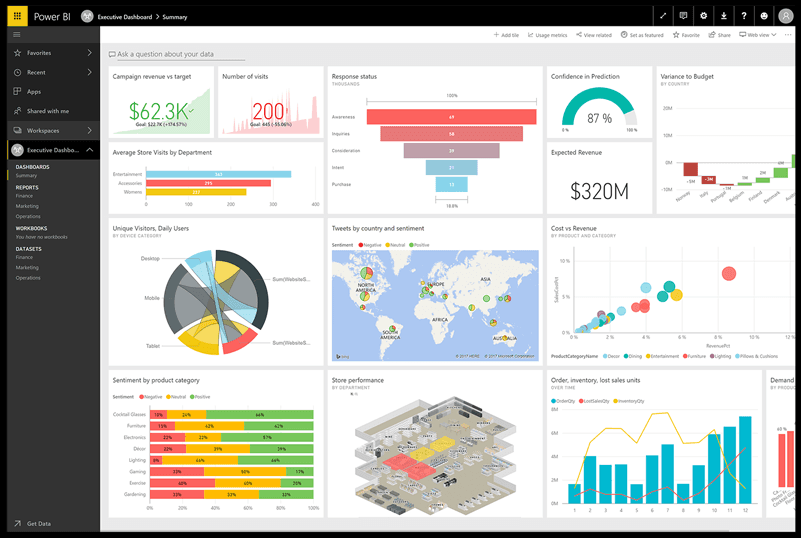

Enhanced production efficiency involves using consulting services to gain real-time insights into manufacturing processes and performance. Consulting helps track key metrics, evaluate production efficiency, and identify opportunities for improvement.

Example: Implementing a manufacturing dashboard to monitor KPIs such as OEE and cycle time, leading to more effective process optimizations and faster identification of potential inefficiencies.

Benefit: Enhanced visibility into production efficiency enables faster decision-making and improves the effectiveness of manufacturing efforts

Optimized Manufacturing Strategies

Optimizing manufacturing strategies means using consulting services to streamline operations and maximize resource utilization. Consulting helps identify inefficiencies, automate processes, and enhance the overall production workflow.

Example: Using process optimization to develop tailored manufacturing plans that address specific production needs, resulting in higher efficiency and reduced costs.

Benefit: Better manufacturing strategies increase efficiency, reduce waste, and enhance production outcomes.

Operational Outcome Prediction

Operational outcome prediction involves using consulting services to anticipate and mitigate potential disruptions associated with manufacturing processes. Consulting can predict trends such as equipment failures or changes in production demand, enabling proactive management.

Example: Applying predictive analytics to forecast the impact of equipment maintenance schedules on production throughput, allowing companies to adjust their strategies and ensure continuous operation.

Benefit: Proactive operational outcome prediction enables companies to stay ahead of potential disruptions, reduce downtime, and achieve desired production outcomes.

By leveraging manufacturing consulting, businesses can gain critical insights, optimize production operations, and predict operational outcomes more effectively, leading to improved manufacturing performance and competitive advantage.

CaseWhen's Innovative Approach

Unique Methodology for Manufacturing Consulting

At CaseWhen, we redefine manufacturing consulting with an innovative methodology that surpasses traditional approaches. Our blend of advanced data analysis techniques and industry expertise provides actionable insights that drive strategic production decisions.

Advanced Analytics Techniques and Industry Expertise

What sets CaseWhen apart is the integration of cutting-edge analytics with deep manufacturing knowledge. This powerful combination offers a comprehensive understanding of your unique manufacturing challenges and opportunities, enabling us to develop tailored solutions that deliver measurable results.

Customized Solutions for Your Business

Recognizing that one-size-fits-all doesn’t work in manufacturing consulting, CaseWhen designs customized solutions that align with your specific production goals and requirements. Whether you need advanced process optimization, efficiency assessments, or comprehensive manufacturing plans, we ensure our solutions are tailored to meet your business objectives.

Tailored Strategies: Solutions designed to meet your specific production needs.

Expert Insights: Leverage our deep industry knowledge for a competitive edge.

Proven Results: Enhance manufacturing performance with data-driven decisions.

Unlock the full potential of your manufacturing data with CaseWhen’s Manufacturing Consulting Service. Let us help you transform insights into actionable strategies that drive your business forward.